DIGITAL MANUFACTURING SYSTEM

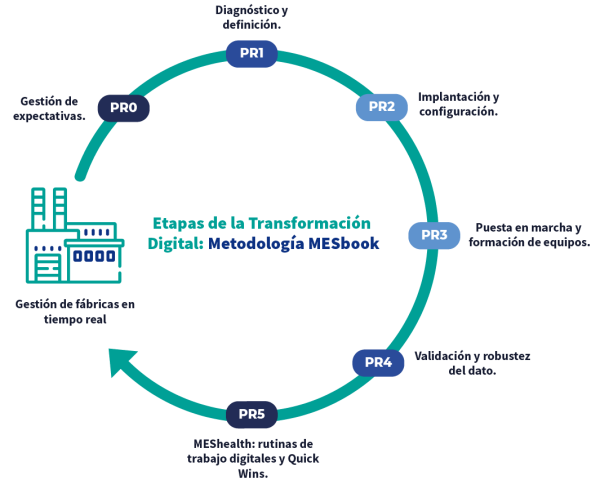

Metodología creada por MESbook para asegurar el éxito en los procesos de Digitalización de Proyectos Industriales

Industria 4.0

Reto al que nos enfrentamos en un Proyecto de Transformación Digital

El reto al que nos enfrentamos en un proyecto de Transformación Digital es fundamentalmente mejorar la cuenta de PyG de nuestros clientes, generando ahorros a través de la eficiencia operacional y la tecnología.

En MESbook tenemos claro que la Clave del Éxito para la Transformación Digital Industrial es la Dirección de Proyectos Industriales, y para conseguirlo, aplicamos nuestra metodología DMS en el marco de la Industria 4.0 para abordar cada uno de los proyectos de digitalización, enfrentándonos a la complejidad de los entornos industriales y asegurando el éxito en cada cliente.

Qué es el Digital Manufacturing System (DMS)

Digital Manufacturing System (DMS) es la metodología creada por MESbook para digitalizar con éxito el proceso de fabricación de una empresa.

Esta metodología consiste en convertir un proyecto enorme y de difícil implementación, en pequeños proyectos abarcables y estructurados bajo objetivos específicos, con responsables por departamento y con fechas que aseguran resultados tangibles.

Fases de la Metodología DMS de MESbook

En esta fase se plantea un escenario inicial del estado de la empresa (AS IS) y una propuesta de escenario final (TO BE).

AS IS: Cómo está trabajando el LEGADO hoy (particularmente máquinas, sistemas y procesos).

TO BE: Cómo vamos a hacer esas tareas de manera digital. Esto aplica sobre todo a los procesos:

- Usabilidad

- Mapeo inicial

- Hacer más eficiente la toma de decisiones

- Estandarizar el proceso

Duración aproximada de dos meses.

PR1.

Diagnóstico y Definición

PR2.

Implantación del Sistema MES y Configuración

Durante esta fase se realiza la conexión a máquinas y sistemas existentes e instalación del software MESbook.

- Instalamos software y hardware.

- Lo conectamos a máquinas y a los sistemas existentes del legado (ERP, Fichadas, etc.).

- Configuramos la nueva plataforma de trabajo de acuerdo al TO BE.

- Validación completa.

Duración aproximada de un mes.

En esta fase se persigue conseguir la validación de la solución implantada a través de procesos R@R (Run@Rate) donde se valida, junto al cliente, todas las funcionalidades en todo el alcance del proyecto.

Así como la formación a los usuarios en todas las capas organizativas: Generalista (super-users) y detallada (key-users).

En función de competencias y responsabilidades de los usuarios, ya que cada uno requiere de una formación y una forma distinta de interactuar con el sistema:

- Directivos

- Mandos intermedios

- Supervisores

- Operarios

Duración aproximada de un mes.

PR3.

Puesta en marcha y Formación de Equipos

PR4.

Validación y Robustez del Dato

En esta fase realizamos lo que llamamos en MESbook las “1.000 vueltas al circuito”.

Nuestro equipo de Customer Succces Management (CSM), especialistas en LEAN, realizará una labor fundamental. En este proceso se asigna a cada cliente un Key Account Manager. Además, se realiza un nuevo funcional con el cliente orientado a objetivos de negocio.

Duración aproximada de dos meses.

Durante esta fase se realiza la implantación de Quickwins y proyectos de mejora. Estos son:

- Quitar papel.

- Maximizar la fiabilidad del sistema de calidad a partir de la validación de resultados en tiempo real, alertas, mensajería y análisis y gestión digital.

- Actualizar los estándares de producción y productividad a partir de las medidas reales obtenidas. Valor asintótico: que es la media de los resultados obtenidos en un universo tan amplio como se determine.

- Incorporación de estos datos a las dinámicas de revisión de desempeño.

- Proyecto de velocidad, mantenimiento sencillo.

PR5.

MEShealth: Rutinas de trabajo digitales y Quick Wins

Por qué contratar un Sistema MES implantado con la metodología DMS en la Industria

- Identificación de los objetivos y expectativas del cliente

- Auditoría del método de trabajo (AS-IS) y diseño de la hoja de ruta para la transformación digital (TO-BE)

- Seguimiento y cumplimiento de los hitos funcionales para la implantación y validación del proceso de transformación digital

- Comité de proyecto

- Seguimiento y cumplimiento de los hitos funcionales para la explotación del sistema de trabajo digital

- Indicadores de alcance y rendimiento

- Gestión y transmisión del conocimiento para la correcta explotación del sistema de trabajo digital

- Despliegue de planes de acción correctivas para cubrir las desviaciones del proyecto

- Evaluación del éxito del proyecto

¿Estás interesado en conocer más sobre nuestra metodología?

Ponte en contacto con nosotros y te contaremos cómo podemos ayudarte