LEANBOOK - METODOLOGÍA LEAN PARA TU FÁBRICA

Realiza una mejora integral de tu negocio con un sistema que se adapta a las necesidades reales de tu fábrica

¿Qué es LEANbook?

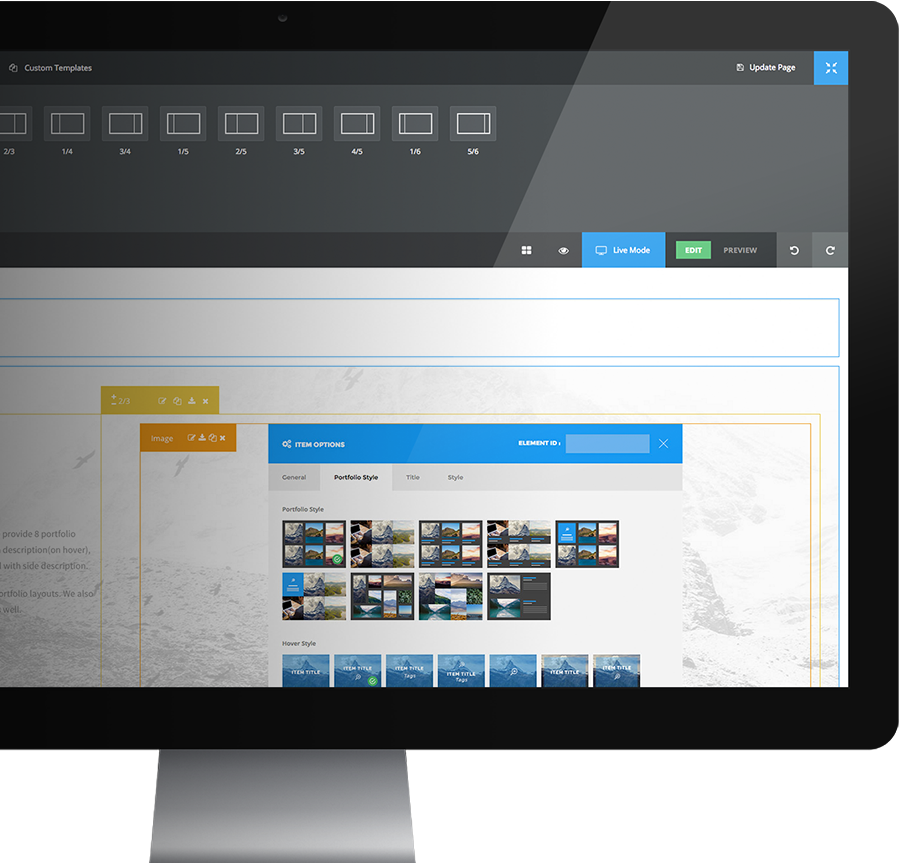

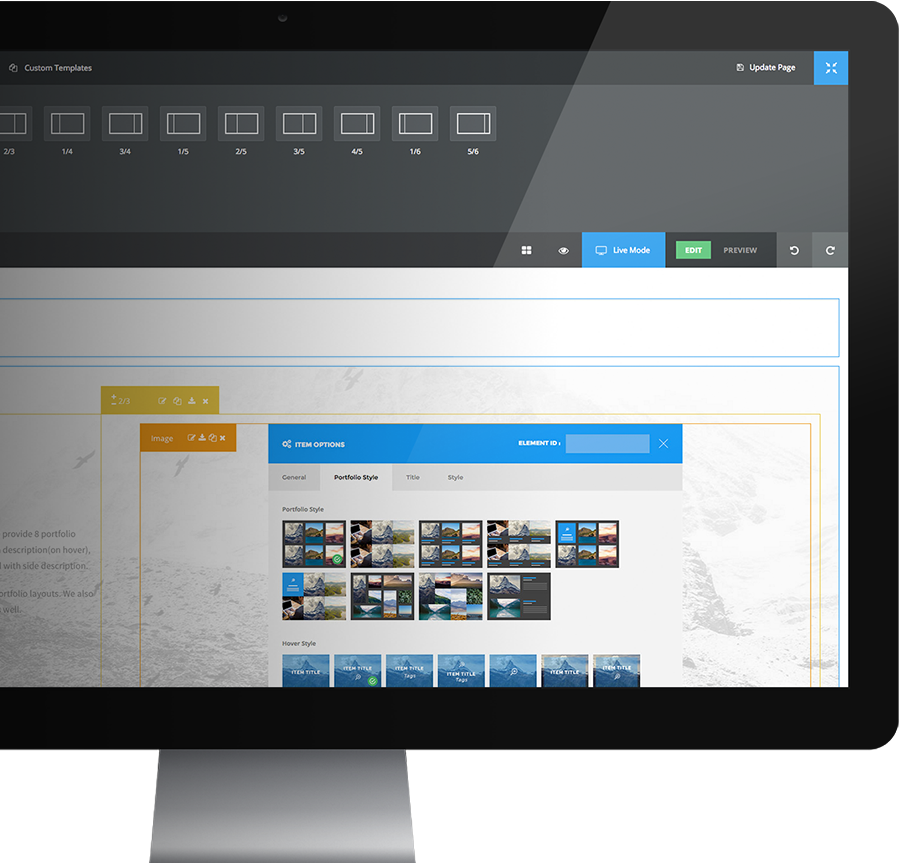

LEANbook es un sistema creado por MESbook basado en la Metodología Lean que proporciona la conexión entre los problemas identificados en las fábricas y sus soluciones para impactar en la cuenta de resultados, y que se alimenta desde un sistema conectado en tiempo real a las personas, las máquinas, los materiales, los sistemas y los procesos.

LEANbook no es una revolución del LEAN sino una evolución, actuando como facilitador de la metodología y sus herramientas para conseguir una mejora continua ágil, eficiente y sostenible.

¿Qué objetivo persigue LEANbook?

El módulo de LEANbook facilita todas las herramientas digitales del método LEAN MANAGEMENT, LEAN PROJECT, LEAN DESIGN, LEAN MANUFACTURING y LEAN LOGISTIC, para una mejor gestión de la mejora integral del negocio.

Simplifica procesos complejos y genera un mayor retorno con la menor inversión

Módulo negocio

Ofrece un diagnóstico del negocio bajo el soporte de más 25 años de experiencia para alcanzar la excelencia en LEAN 4.0. Por otro lado, conecta la estrategia, los presupuestos y los planes con el negocio en tiempo real y con una única herramienta. Finalmente monetizando todos los planes de acción.

MÓDULO PRODUCTO

Gestiona el plan de negocio con herramientas de gestión ágil de proyectos, focalizando el coste de producción hacia el valor para el cliente. Todo ello, asegurando el diseño correcto a seguir a la primera.

MÓDULO PROCESOS

Facilita todas las herramientas apropiadas para garantizar que los equipos, los procesos y las personas están disponibles de la manera más adecuada y eficiente. Con él se garantiza trazar de la manera más ágil cualquier producción o NC.

MÓDULO PERSONAS

Centrado en inculcar la cultura e implicación del personal de manera que se puedan explotar las herramientas necesarias para alinear a todos los trabajadores. Con el beneficio de gestionar el rendimiento de toda la plantilla desde una única interface.

MÓDULO CADENA DE SUMINISTRO

Estabiliza el proceso de entrada de la demanda de cliente y traslado en cascada a la línea de producción y proveedores. Todo ello es posible con la gestión de la cadena de suministro y el control preventivo de inventarios.

Ventajas de implantar el módulo LEANbook en tu fábrica

- Facilidad en la implantación y sostenibilidad del sistema LEAN

- Reducción de los tiempos de respuesta a los problemas

- Minimiza o elimina las tareas que no aportan un valor añadido ahorrando en costes directos e indirectos

- Agiliza la comunicación y el control de incidencias

- Conexión a tiempo real con las tareas tácticas y operativas, mostrando su estado, responsable, calendario y toda la comunicación colaborativa

¿Estás interesado en el módulo LEANbook?

Ponte en contacto con nosotros y te contaremos cómo podemos ayudarte