SOFTWARE DE GESTIÓN

DE ALMACENES - SGA

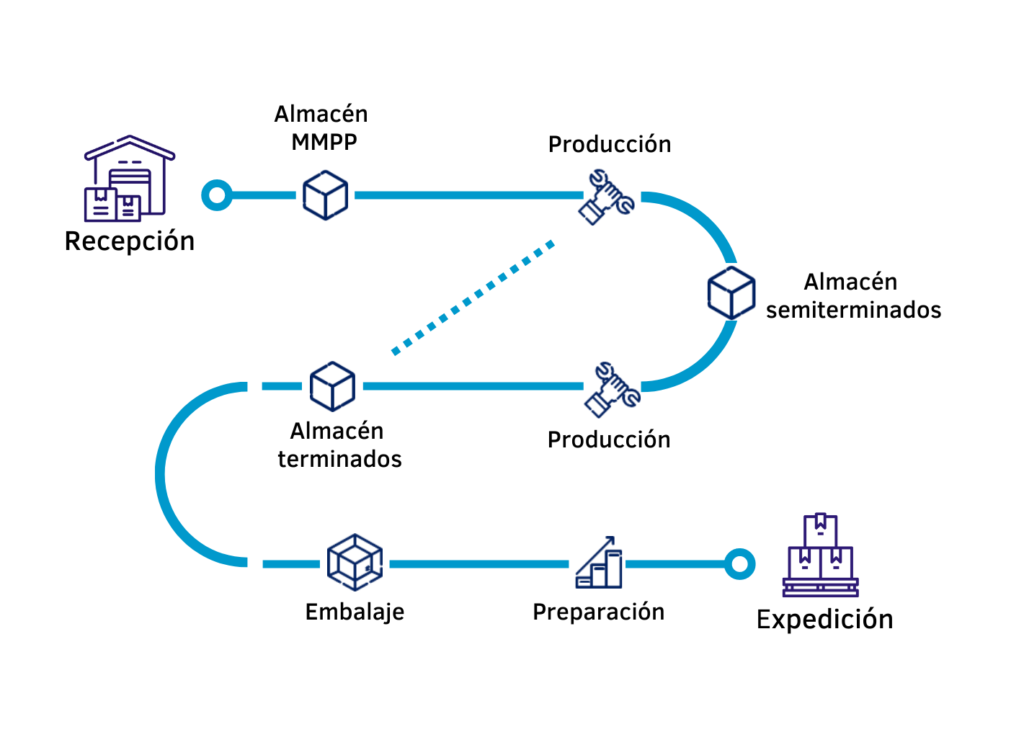

Controla y optimiza todos los procesos de gestión de tu almacén conectado con la fábrica

SGA para la gestión de inventarios y logística interna

Podrás realizar una gestión de las fabricaciones y consumos de materiales, semielaborados y producto final directamente desde MESbook, que comunicará en tiempo real con el ERP, multiplicando su eficiencia y rentabilidad.

Claves para la gestión de almacenes en Industria 4.0

Fiabilidad de inventario

Movimiento físico igual a movimiento informático, en tiempo real.

Fiabilidad en el stock intermedio de materias primas e intermedias.

Robustez y trazabilidad en el flujo de movimientos de materiales.

Eficiencia

Maximizar la eficiencia de toda la operativa logística en la digitalización de procesos.

Fluidez en los flujos de producto e información.

Mejora de tiempos y disminución de errores y costes logísticos.

Análisis

Capacidad de almacenaje.

Análisis de Movimientos.

Trazabilidad de movimientos de los materiales.

Soluciones logísticas de almacenamiento automático

Qué incluye el módulo SGA de MESbook

Gestión de entradas, movimientos y salidas de material

- Recepción de producto e inclusión de criterios de Calidad (inspecciones, validaciones, etc.).

- Transacciones de materiales (materias primas, productos semielaborados y productos terminados).

- Gestión de salidas: preparación de picking a partir de pedido, generación de albaranes, descuento de producto y programa de gestión de almacenes comunicado con el ERP en tiempo real.

Preparación material para producción, fabricación y consumos

- Preparación de material para órdenes de fabricación.

- Flexibilidad: Incorporar nuevas materias primas, materiales alternativos, nº de lotes no contemplados. Nos adaptamos en todo momento.

- Alta de fabricaciones y consumos reales o automáticos contra escandallo.

- Conexión a células de carga, caudalímetros, etc.

Ubicaciones, gestión y análisis de stocks

- Definición de ubicaciones para toda la fábrica: almacén central, intermedios, en líneas de fabricación, etc.

- Funcionalidad de control de obsolescencia, en función de consumos reales y proyección futura parametrizable.

- Gestión de stocks, con clasificación ABC parametrizable, análisis autónomo y alertas para la ejecución de recuentos cíclicos.

Ventajas de un sistema SGA en fábricas

REDUCCIÓN DE COSTES OPERACIONALES

Optimiza la ubicación y distribución de la mercancía de tu fábrica y minimiza las tareas manuales del personal mediante la digitalización de la operativa, gracias a nuestro avanzado software para gestión de almacenes.

VISIBILIDAD COMPLETA DEL INVENTARIO

Registrando las entradas, salidas y reubicaciones del material podrás tener controlado todo el inventario, lo que te permitirá optimizar las previsiones de demanda.

INTEGRACIÓN CON LA CADENA DE VALOR

La digitalización del almacén de tu fábrica con nuestro programa de gestión de almacenes te permitirá integrar los datos recogidos con el resto de información automatizada de tu fábrica.

SEGURIDAD

Con la implantación de un SGA podrás mejorar la seguridad del flujo de información que se gestiona en el almacén. Además, permite una completa trazabilidad sobre los distintos movimientos de la mercancía.

PREGUNTAS FRECUENTES

Sí, el módulo SGA de MESbook incluye kanban electrónico multicomponente, con alertas que avisan cuando un componente está por debajo de su stock de seguridad y debe realizarse el aprovisionamiento de material.

Los aprovisionamientos a línea de los materiales necesarios para fabricar se gestionan a través de nuestro módulo de almacén/ SGA, donde se realizan los traspasos de las materias primas desde un almacén central hasta la ubicación de la línea. Los traslados se realizan a través de recipientes con trazabilidad unívoca. Cuando ese recipiente se traslada a la línea, se genera disponibilidad del lote de la materia prima que lo contiene y de esta manera el operario puede consumir ese componente contra su BOM en la orden de fabricación abierta en esa línea de fabricación.

¿Estás interesado en el módulo SGA?

Contacta con nosotros para solicitar una demo o presupuesto personalizado