SOFTWARE GMAO

Sistema de planificación y control del mantenimiento en las fábricas

Conéctate a la realidad de la fábrica

Optimiza las tareas de mantenimiento y reduce los tiempos de inactividad con el software GMAO

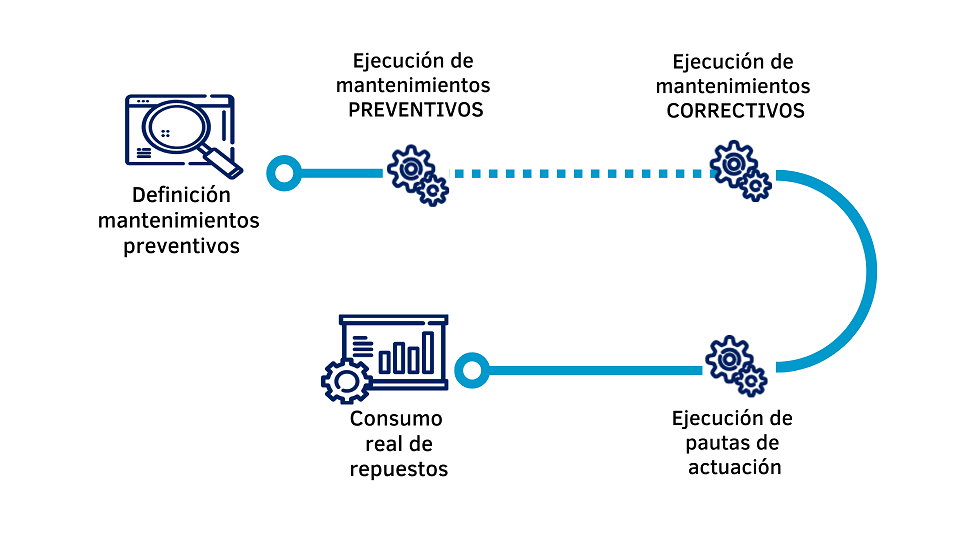

Mesbook permite la definición de mantenimientos preventivos y las pautas de actuación sobre cada una de las líneas, guiando al operario en todo momento. Interconectado con el almacén de repuestos y calculando los agujeros de coste en materiales y mano de obra.

El software GMAO de Mesbook lanza planes correctivos y almacena la información para facilitar la resolución en futuras actuaciones.

Problemas identificados en la gestión del mantenimiento

- Productividades bajas: El 12% de la productividad depende del rendimiento y la disponibilidad de la maquinaria.

- Altos costes y baja efectividad del mantenimiento de maquinaria.

- Recopilación de datos manual, en papel, poco fiable y proceso costoso.

- No se almacena la información ni se explota para futuras actuaciones.

- No se controla el coste de mano de obra ni el coste de repuestos.

- No se lleva control del almacén de repuestos.

Qué incluye el software GMAO de MESbook

- Planes de mantenimiento preventivos, predictivos y correctivos con la herramienta GMAO

- Vinculación de los controles de cada máquina a cada línea de fabricación

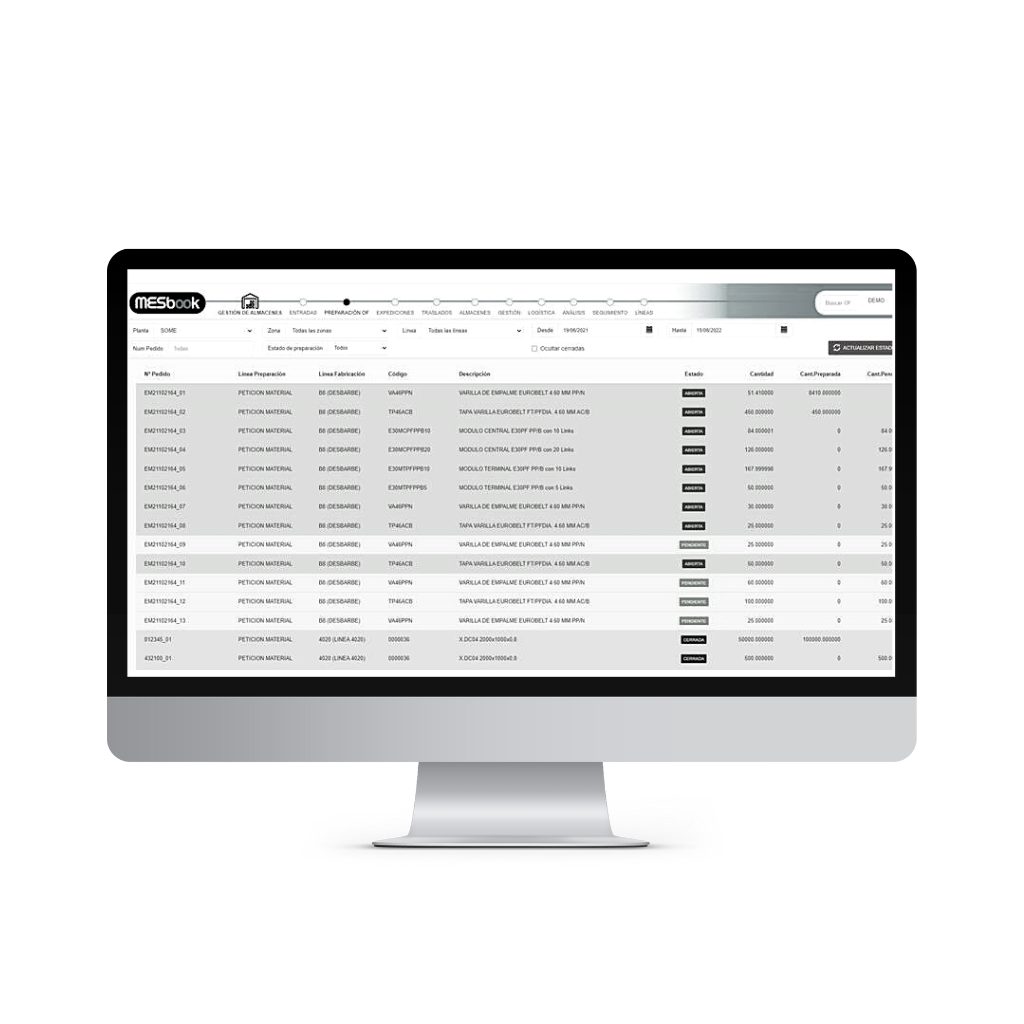

- Información consolidada de todas las Órdenes de Mantenimiento en una única pantalla, obteniendo el conocimiento de posibles retrasos que puedan existir de la ejecución de las mismas

- Atribución de los controles mediante un registro del operario para conocer cuándo y cómo se ha realizado, y el análisis detallado de la avería.

- Sistema de avisos entre producción y mantenimiento

- Control de costes de mano de obra y de los repuestos

Ventajas de disponer del sistema GMAO de MESbook

Gestión administrativa y conexión a otros sistemas

Documentación, árboles de máquinas, informes, gestión de proyectos y lanzamiento de planes preventivos con periodicidad, personal objetivo y tiempos objetivo.

Comunicación con fábrica

Conexión a máquinas, fichadas de técnicos, reportes TPM y control de alertas.

Planificación de OTs y control

Plan de OTs, control de ejecución, gestión de repuestos, cuadros de mando, visión generalizada de los mantenimientos que se llevan a cabo y control a tiempo real de las actuaciones en las líneas.

FUTURO: PREDICTIVOS

Conexión a PLCs y sensórica específica, control estadístico de procesos, construcción del Dataset y predictor de fallos.

PREGUNTAS FRECUENTES

Un sistema MES (Manufacturing Execution System) es un software utilizado para gestionar y controlar los procesos de producción en una planta de fabricación.

Un sistema GMAO integrado en un sistema MES permite la gestión de los activos y el mantenimiento preventivo y correctivo en tiempo real, lo que optimiza los procesos de producción y maximiza la eficiencia de los activos.

Las principales funciones de un sistema GMAO integrado en un sistema MES incluyen la gestión de órdenes de trabajo, la planificación de mantenimiento preventivo y correctivo, la programación de mantenimiento, la gestión de inventario de piezas de repuesto, y la generación de informes y análisis en tiempo real.

Un sistema GMAO integrado en un sistema MES ofrece varios beneficios, incluyendo la reducción de tiempos de inactividad no programados, la mejora de la eficiencia y la disponibilidad de los activos, la reducción de costos de mantenimiento, la mejora de la calidad del producto, y la optimización de la planificación y ejecución de la producción.

Un sistema GMAO integrado en un sistema MES utiliza una base de datos centralizada que asegura la integridad y la coherencia de los datos en tiempo real. Además, los datos se guardan de forma segura y se accede a ellos a través de un sistema de seguridad de acceso basado en roles.

Un sistema GMAO embebido en un sistema MES puede recopilar datos sobre las averías, como la frecuencia y el tipo de averías que se producen en los activos. Estos datos se pueden utilizar para realizar un análisis de las averías, lo que permite identificar patrones y tendencias en el comportamiento de los activos, y determinar las causas raíz de las averías recurrentes. Este análisis puede ayudar a optimizar el mantenimiento preventivo y a reducir los tiempos de inactividad no planificados, mejorando así la eficiencia y la rentabilidad de la producción.

¿Estás interesado en el módulo GMAO?

Contacta con nosotros para solicitar una demo o presupuesto personalizado