Agricultura 4.0: Qué es y retos

Agricultura 4.0: Qué es y retos Según datos oficiales, la población mundial se acercará a los 10.000 millones de personas en el año 2050. Una

EL PRIMER PODCAST DE INDUSTRIA 4.0

La realidad de la Transformación Digital contado por sus protagonistas

Somos el resultado de 20 años de experiencia gestionando fábricas

Sistema 100% WEB: Interconectado con toda la fábrica

Gracias al aumento de productividad y reducción de los costes.

Servicio de acompañamiento tras finalizar implantación y sin coste adicional

MESbook es un Sistema de Gestión de Fábricas en Tiempo Real (Software MES/MOM y equipo de implantación) que ofrece soluciones de Industria 4.0 a todas las necesidades operacionales de la empresa industrial.

MESbook se conecta a las máquinas de la fábrica y capta señales para transformarlas en datos y posteriormente en información, todo ello, en tiempo real, para conseguir aumentar la productividad y reducir los costes de fabricación.

Infórmate de todas las ayudas y subvenciones tanto estatales como regionales a las que puedes acogerte para financiar tu proyecto de transformación digital en tu fábrica. Desde MESbook te informamos de cómo solicitar la ayuda y te acompañamos en todos el proceso de presentación de la documentación.

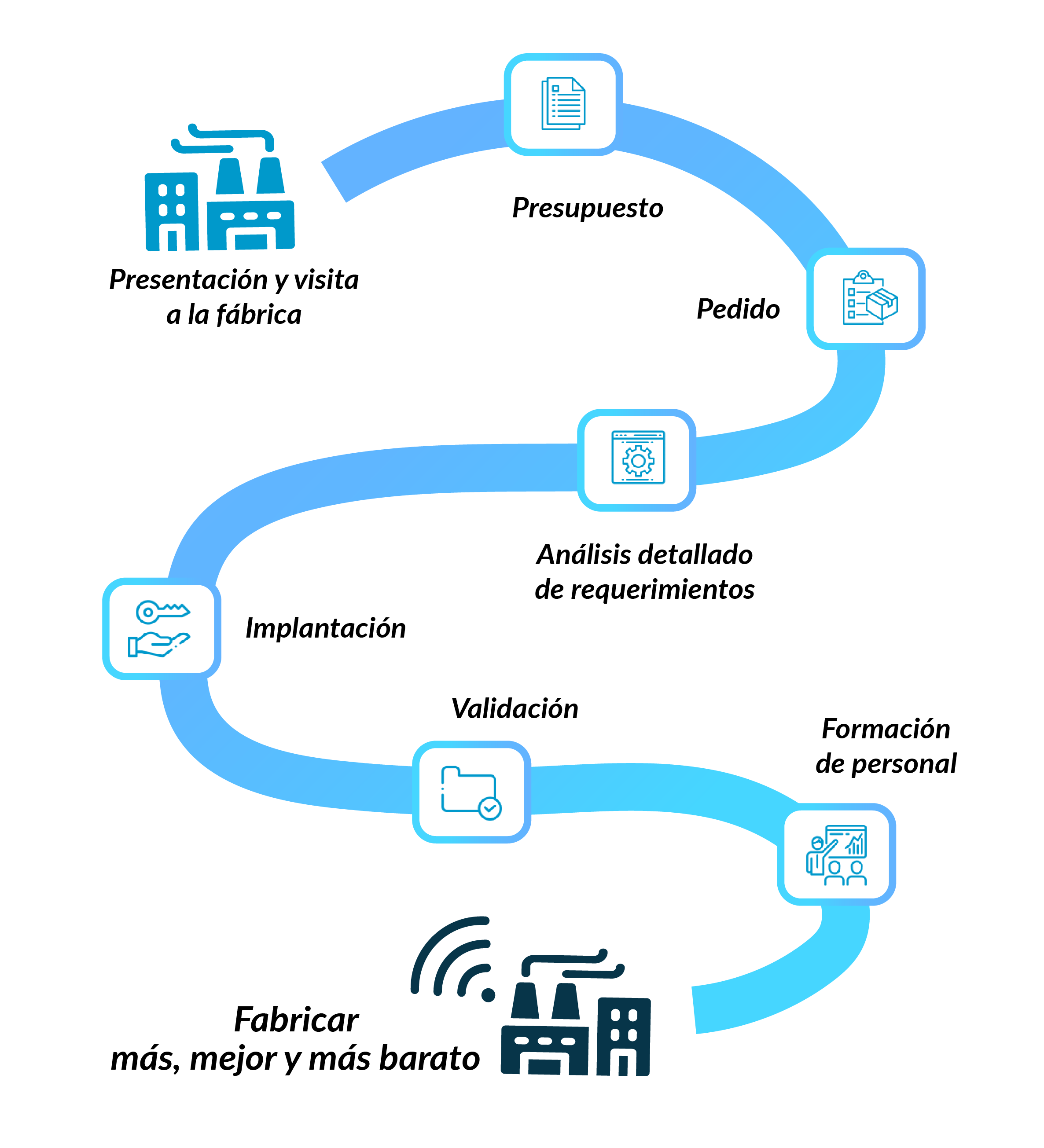

Proyecto llave en mano en 16 semanas, plazos a coordinar con equipo de proyecto y condicionados a tamaño de empresa y alcance funcional.

Realizamos una propuesta a tu medida. Ofrecemos flexibilidad para incrementar/reducir módulos contratados.

MESbook se adapta a cualquier casuística, proceso de fabricación y ERP en fábrica.

Mínima inversión inicial y pago por uso. Ahorras más de lo que cuesta.

Payback < 1 año en todos los casos. Cada € invertido genera en torno a 8€ de ahorro.

Tras la implantación, te ofrecemos un servicio formativo y soporte para el uso eficiente de la herramienta. Incluido en la cuota mensual.

MESbook es capaz de digitalizar todos los procesos de fábrica, adaptándose a las máquinas, personas, sistemas, procesos y cultura empresarial preexistentes, durante el proceso de implantación.

Identifica en tiempo real y en euros las desviaciones y los agujeros de coste en la planta de producción y su origen.

Automatiza la toma de datos. Elimina el coste del papel, la recopilación y toma de datos y los errores.

Controla desde la más simple orden de fabricación hasta el desempeño de toda la fábrica o conjunto de fábricas.

Toma las decisiones correctas, define y controla los proyectos de mejora con mayor ahorro potencial.

Asegura la base para la digitalización de futuras tecnologías.

Propuestas a medida en cada proyecto

Módulos MESbook

Amplía Información

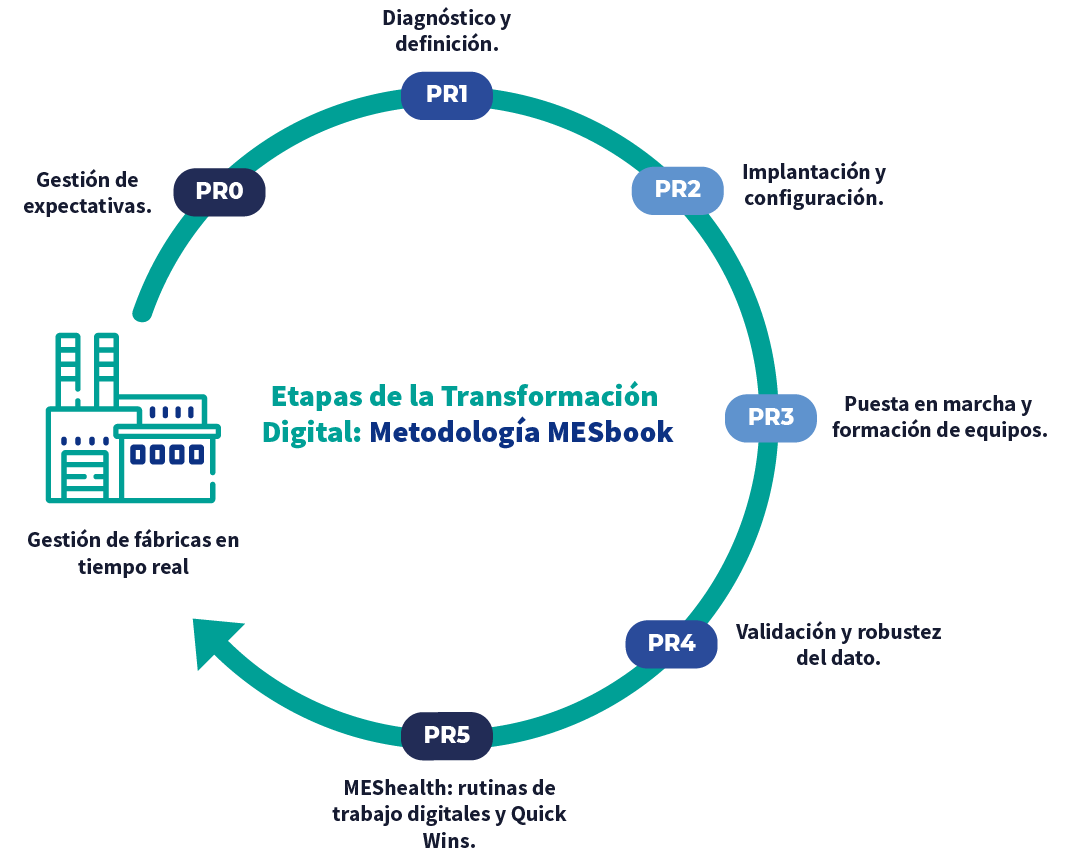

Metodología 4.0 creada por MESbook para digitalizar con éxito el proceso de fabricación de una empresa

Digital Manufacturing System

Con nuestra metodología DMS convertimos un proyecto enorme y de difícil implementación, en pequeños proyectos abarcables y estructurados bajo objetivos específicos, con responsables por departamento y con fechas que aseguran resultados tangibles.

En MESbook seguimos un proceso riguroso para asegurar la correcta implantación del producto, con el objetivo de mejorar la productividad de las empresas.

Sectores en los que operamos

Agricultura 4.0: Qué es y retos Según datos oficiales, la población mundial se acercará a los 10.000 millones de personas en el año 2050. Una

El riesgo de la obsolescencia tecnológica En el momento actual de la industria, la obsolescencia tecnológica se está convirtiendo en un riesgo cada vez más

MESbook, el primer sistema MES/MOM con tecnología Blockchain El primer sistema MES/MOM con tecnología Blockchain llega de la mano de Mesbook. En este post repasamos

De la automatización a la humanización: El avance de la industria 5.0 La Cuarta Revolución Industrial, más conocida como Industria 4.0, define la integración de tecnologías

¿Qué es la ISO 9001 y para qué sirve? La ISO 9001:2015 es una norma internacional ampliamente reconocida a nivel mundial que se ha convertido

Metodología 5S en la Industria Automotriz La Metodología 5S se centra en la optimización y la organización en la Industria Automotriz. Si deseas descubrir cómo

Suscríbete a nuestra newsletter

Mantente informado de todas las novedades en Transformación Digital e Industria 4.0 de la mano de MESbook.