MESbook, the first MES/MOM system with Blockchain technology

MESbook, the first MES/MOM system with Blockchain technology The first MES/MOM system with Blockchain technology comes from Mesbook. In this post we review

THE FIRST INDUSTRY 4.0 PODCAST

The reality of Digital Transformation told by its protagonists.

We are the result of 20 years of experience in factory management

100% WEB system: Interconnected with the entire factory.

Thanks to increased productivity and reduced costs.

After the implementation is completed and at no additional cost

MESbook is a Real-Time Factory Management System (MES/MOM software and implementation equipment) that offers Industry 4.0 solutions to all the operational needs of the industrial company.

MESbook connects to the factory machines and captures signals to transform them into data and then into information, all in real time, to increase productivity and reduce manufacturing costs.

Find out about all the state and regional grants and subsidies that you can apply for to finance your digital transformation project in your factory. From MESbook we will inform you on how to apply for the aid and we will accompany you throughout the process of submitting the documentation.

Turnkey project in 16 weeks, deadlines to be coordinated with project team and conditioned to company size and functional scope.

We make a proposal tailored to your needs. We offer flexibility to increase/reduce contracted modules.

MESbook adapts to any casuistry, manufacturing process and ERP in the factory.

Minimum initial investment and pay-as-you-go. You save more than it costs.

Payback < 1 año en todos los casos. Cada € invertido genera en torno a 8€ de ahorro.

After the implementation, we offer you a training and support service for the efficient use of the tool. Included in the monthly fee.

MESbook is able to digitize all factory processes, adapting to the pre-existing machines, people, systems, processes and company culture during the implementation process.

Identifies in real time and in euros the variances and cost holes in the production plant and their origin.

Automates data collection. Eliminates the cost of paper, data collection, data capture and errors.

It controls from the simplest manufacturing order to the performance of the entire factory or set of factories.

Make the right decisions, define and monitor improvement projects with the greatest potential savings.

It secures the basis for the digitisation of future technologies.

Tailor-made proposals for each project

MESbook modules

More information

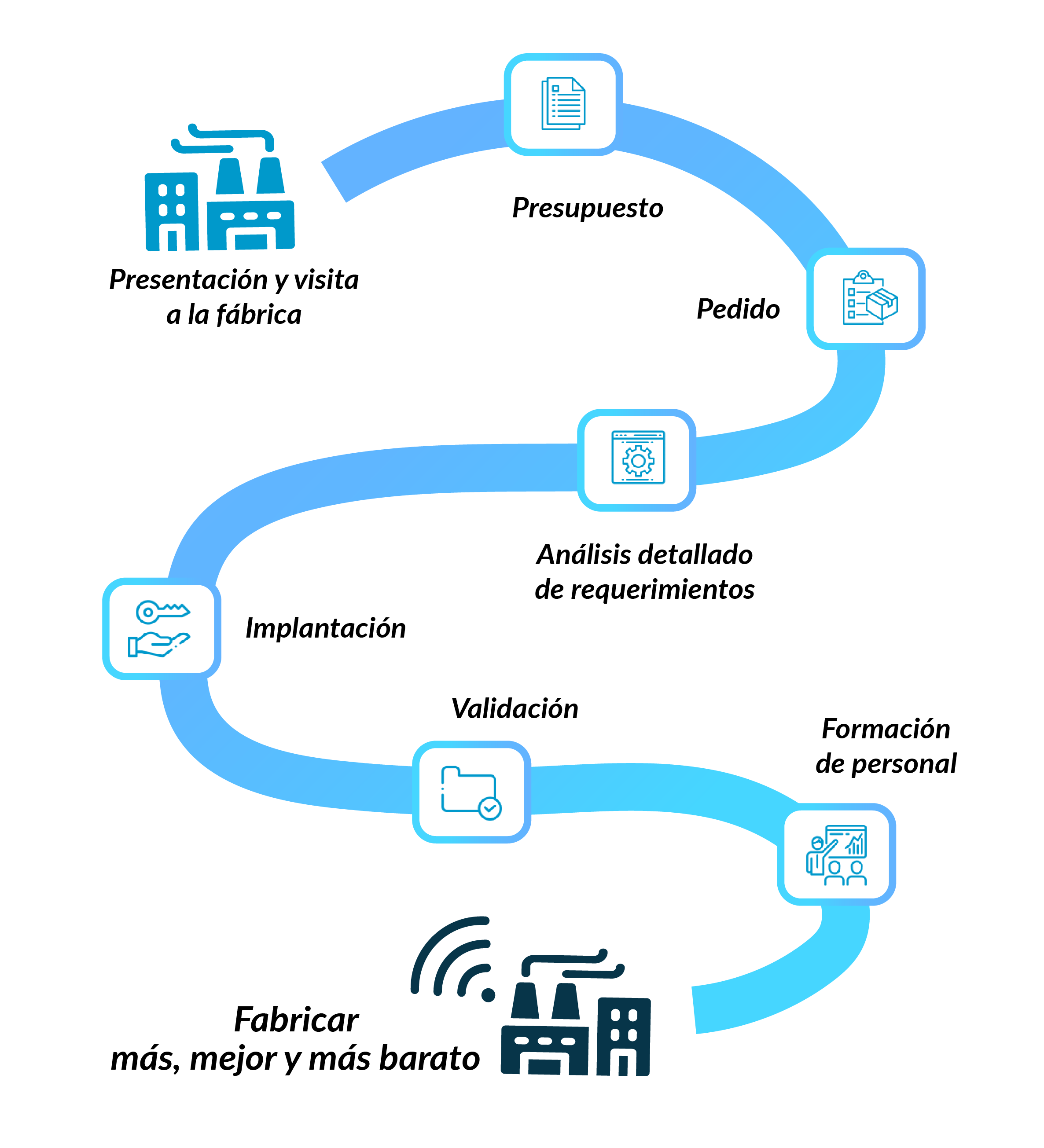

Methodology 4.0 created by MESbook to successfully digitize a company's manufacturing process.

Digital Manufacturing System

With our DMS methodology, we turn a huge and difficult to implement project into small, manageable projects structured under specific objectives, with departmental managers and dates that ensure tangible results.

At MESbook we follow a rigorous process to ensure the correct implementation of the product, with the objective of improving the productivity of the companies.

MESbook, the first MES/MOM system with Blockchain technology The first MES/MOM system with Blockchain technology comes from Mesbook. In this post we review

From automation to humanization: Advancing Industry 5.0 The Fourth Industrial Revolution, more commonly known as Industry 4.0, defines the integration of technologies

What is ISO 9001 and what is it for? ISO 9001:2015 is an international standard that is widely recognized worldwide and has become a standard that has become

5S Methodology in the Automotive Industry The 5S Methodology focuses on optimization and organization in the Automotive Industry. If you want to discover how

Importance of data analytics in Industry 4.0 Industry 4.0 is an industrial revolution that is transforming the way we do business.

Examples of industrial automation Industrial automation is applied in a wide variety of industries and processes and has very diverse applications. Here are just a few of them

Subscribe to our newsletter

Keep up to date with all the latest news on Digital Transformation and Industry 4.0 with MESbook.